In the industrial landscape, efficient material handling is crucial for businesses to maintain productivity and competitiveness. When faced with complex spatial layouts and diverse processing requirements, Zhengzhou Tianqi Machinery Co., Ltd. emerges as a reliable partner, offering customized mesh belt conveyor solutions. These solutions are designed to help industries such as cement and paper achieve efficient material handling and system integration optimization.

Zhengzhou Tianqi Machinery adopts a comprehensive custom - design approach that starts from customer needs research. The company's experts engage in in - depth discussions with clients to understand their specific requirements, including the nature of the materials to be transported, the layout of the production site, and the expected throughput. After that, they move on to setting the technical parameters. This involves determining factors such as the conveyor's speed, capacity, and inclination angle. Finally, the system integration phase ensures that the conveyor seamlessly fits into the client's existing production system.

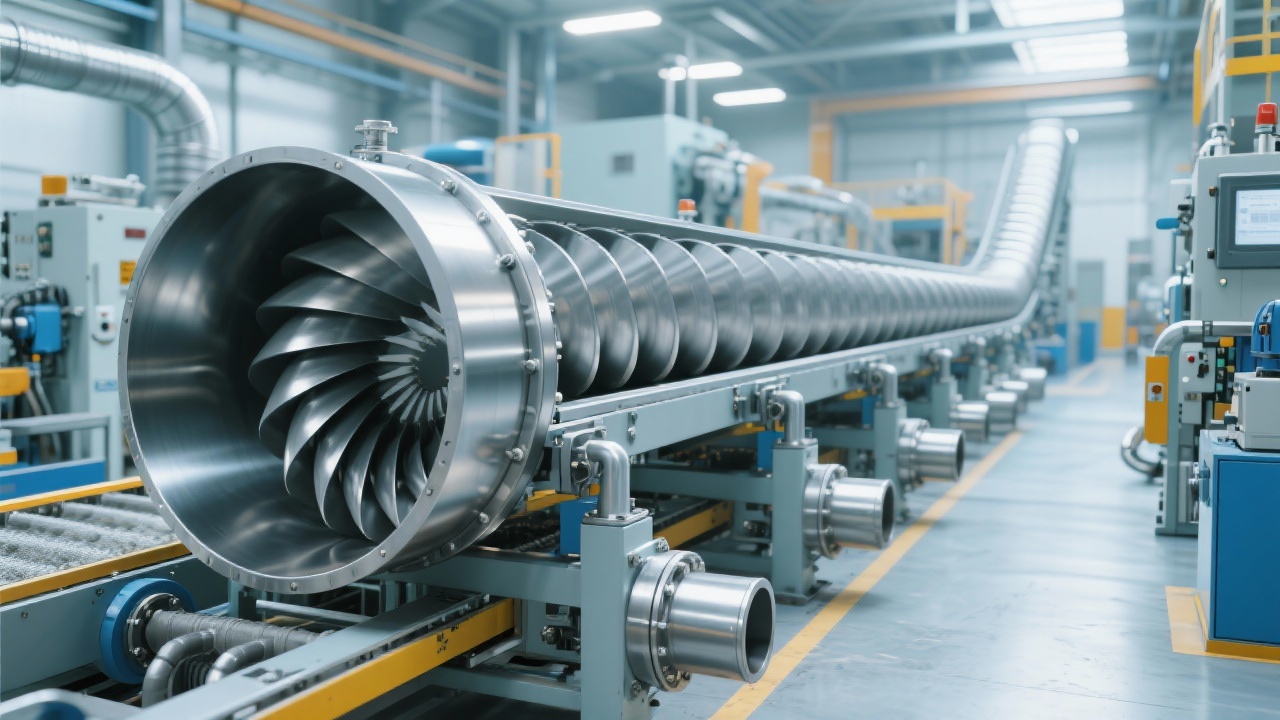

The separate traction chain and carrier chain structure is a core technology of Zhengzhou Tianqi's mesh belt conveyors. This innovative design significantly reduces maintenance costs. Since the traction chain and the carrier chain are separated, it is easier to identify and replace damaged parts. This not only simplifies the maintenance process but also reduces the downtime of the conveyor. For example, in traditional conveyor designs, a single chain failure could lead to a complete shutdown of the system. With the separate chain design, the impact of a chain failure is minimized, and the conveyor can often continue to operate with reduced capacity until the damaged part is replaced.

In the cement industry, the conveyor needs to handle large - volume materials at various angles. Zhengzhou Tianqi's mesh belt conveyors can achieve a conveying capacity of up to 526 cubic meters per hour and can operate at an inclination angle of up to 60°. These conveyors can also withstand high - temperature conditions of up to 600°C, ensuring stable operation in the harsh cement production environment. In the paper industry, where materials are often bulky and require careful handling, the conveyors can handle the high - volume and multi - angle transportation challenges. Real - world case studies show that the conveyors can effectively meet the industry's needs for efficient material handling.

For industrial customers, continuous operation is of utmost importance. Zhengzhou Tianqi Machinery understands this and offers a 98% on - time delivery rate. This means that customers can rely on the company to provide the conveyors within the agreed - upon time frame, ensuring that their production schedules are not disrupted. In addition, the company provides a 2 - hour quick - response service. In case of any issues or emergencies, the company's technical support team can respond within 2 hours, providing solutions to keep the production running smoothly.

To make the information more accessible and professional, Zhengzhou Tianqi incorporates visual elements such as data charts and flowcharts. Data charts can clearly show the performance indicators of the conveyors, such as the relationship between the conveying capacity and the inclination angle. Flowcharts can illustrate the custom - design process, making it easier for customers to understand how their requirements are translated into a practical solution.

Your production line needs such an intelligent conveying solution. Zhengzhou Tianqi Machinery's customized mesh belt conveyors can be the key to optimizing your material handling process and improving overall productivity. Don't miss out on the opportunity to enhance your operations. 立即获取专属定制方案 (Get your exclusive customized solution now)