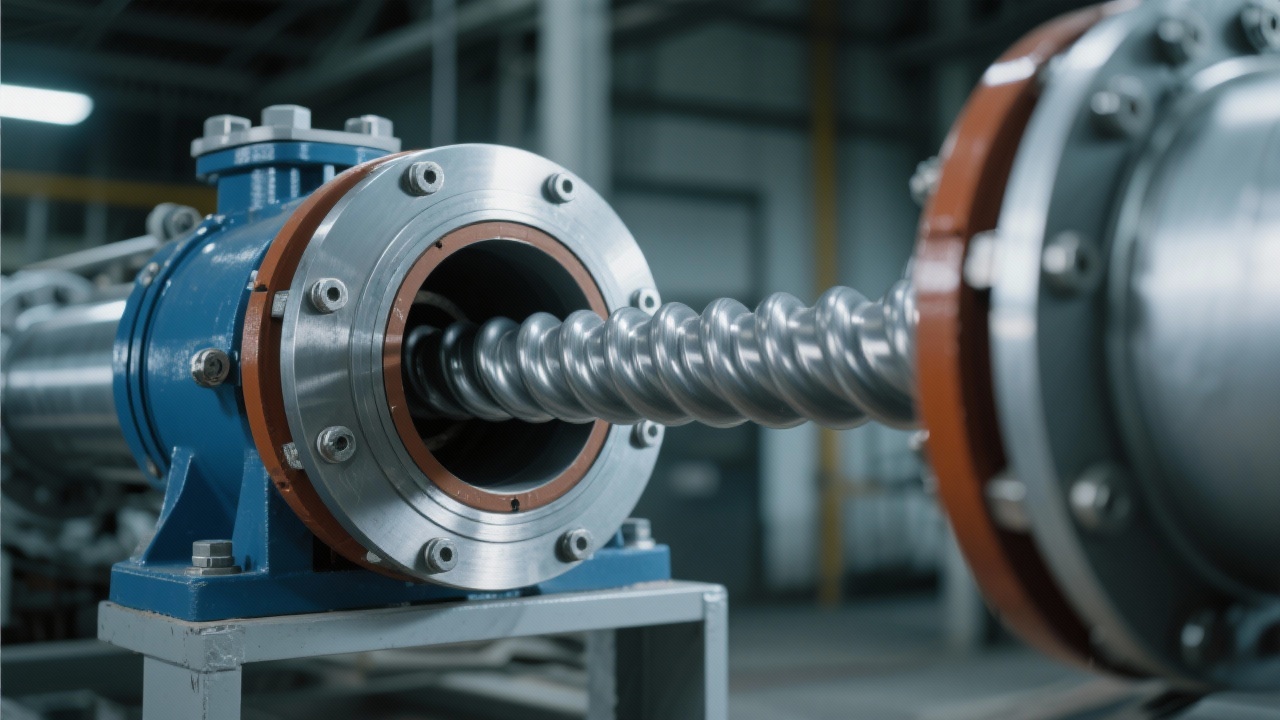

In modern industrial production, the efficient and safe transportation of materials is crucial. Heavy-duty screw conveyors, as a key equipment for material transportation, have attracted wide attention due to their unique sealed operation technology and excellent dust control performance. This article delves into the technical details of these conveyors and their practical applications.

The performance of heavy-duty screw conveyors is mainly determined by several key parameters. For example, the design of the screw rotor is of great significance. A well - designed screw rotor can ensure a stable conveying speed, usually ranging from 0.5 to 2 meters per second. The conveying distance can reach up to 30 meters, and the lifting height can reach 10 meters, which can meet the needs of most industrial production scenarios.

Different material forms, such as powder, granular, and small - block, have different requirements for screw conveyors. Powder materials are prone to dust generation, so higher - level sealing technology is required. Granular materials have relatively good fluidity, but attention should be paid to the wear of the equipment. Small - block materials may require a larger screw diameter and higher torque. According to industry statistics, about 60% of powder material transportation requires the use of special sealing devices to ensure dust - free transportation.

The working environment also poses various challenges to the operation of heavy - duty screw conveyors. For example, in high - temperature environments, the material of the conveyor needs to have high - temperature resistance. In humid environments, anti - corrosion measures are required. In some industries with high dust requirements, such as the food and pharmaceutical industries, the conveyor must ensure absolute cleanliness and dust - free.

The sealed operation technology of heavy - duty screw conveyors is the key to dust control. Through the use of advanced sealing materials and structural designs, the dust leakage rate can be reduced to less than 1%. This not only effectively reduces material pollution but also improves the reliability and service life of the equipment. According to a real - world case in a cement plant, after using the new sealing technology, the dust concentration in the workshop decreased by 80%, greatly improving the working environment.

The multi - point feeding and discharging systems of heavy - duty screw conveyors provide great flexibility for production lines. They can be easily integrated into different production processes, improving production efficiency. For example, in an assembly line production, the conveyor can feed materials from multiple points and discharge them at different locations, which is very suitable for the needs of modern flexible production.

Heavy - duty screw conveyors are known for their sturdy structure and low maintenance cost. The use of high - strength materials ensures the long - term stable operation of the equipment. At the same time, the simple structure design reduces the frequency and cost of maintenance. Generally speaking, the annual maintenance cost of a heavy - duty screw conveyor accounts for only about 5% of its total cost.

In conclusion, heavy - duty screw conveyors play an important role in modern industrial material transportation. If you are looking for high - quality dust - free material conveying solutions, click here to learn more about our heavy - duty screw conveyors and start a consultation with our experts.