Efficient Dust-Free Conveying Solutions: Key Features and Advantages of Heavy-Duty Screw Conveyors

2026-01-15

Product Related

This article provides a comprehensive analysis of selecting heavy-duty screw conveyors tailored for efficient dust-free material handling. It examines critical equipment performance parameters, material characteristics, and environmental requirements to optimize conveying solutions for powders, granules, and small lumps. Emphasizing advanced sealing technology, the discussion highlights its effectiveness in minimizing dust emissions and preventing material contamination. Additionally, the flexible multi-point feeding and discharging configurations are explored for enhancing complex production line adaptability. Targeted at procurement specialists and technical decision-makers in mining, chemical, and construction industries, this guide supports improved operational efficiency and environmental safety through informed selection and application of screw conveyor systems.

Efficient Dust-Free Conveying Solutions: Heavy-Duty Screw Conveyor Features and Benefits

Selecting the right heavy-duty screw conveyor is critical for industries requiring high-efficiency and environmentally safe material handling. This article explores the technical parameters, application contexts, and operational advantages that make certain screw conveyors ideal for dust-free conveying of powders, granules, and small lumps. Emphasizing advanced sealing technology and multi-point feeding designs, this examination caters to procurement experts and technical decision-makers within mining, chemical, and construction sectors who seek to optimize production efficiency while maintaining strict environmental standards.

Foundational Performance Parameters of Heavy-Duty Screw Conveyors

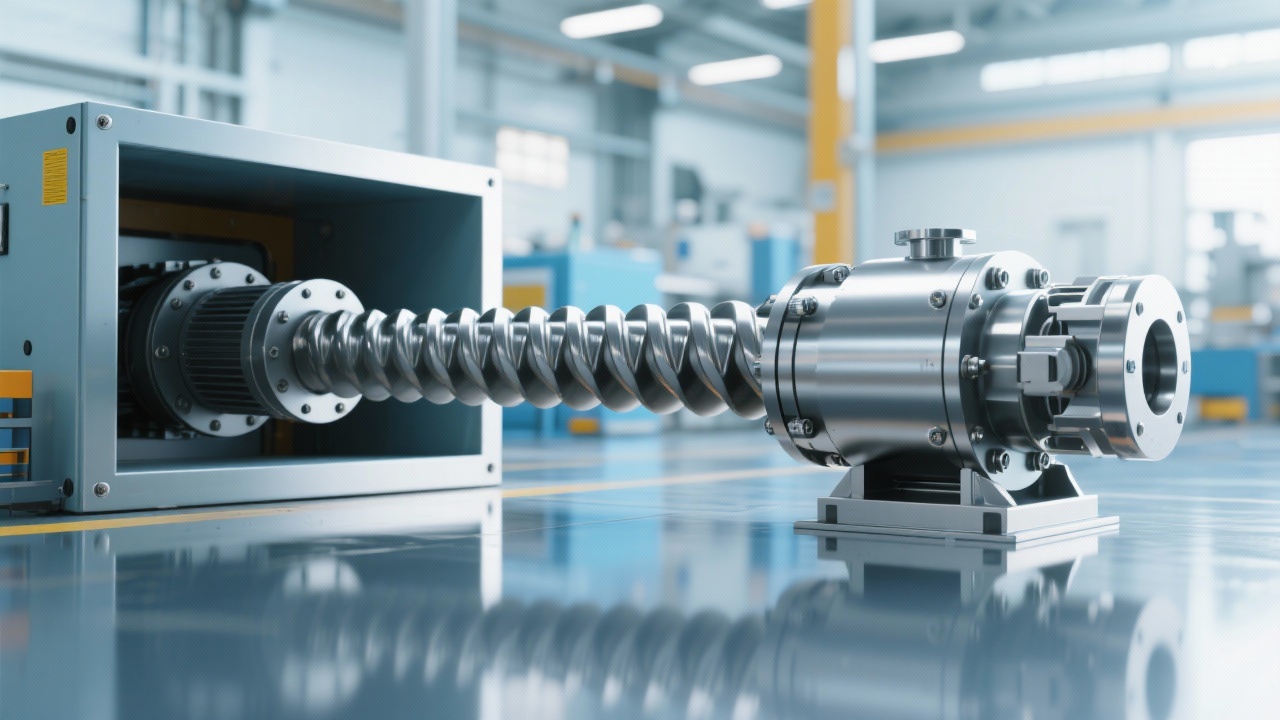

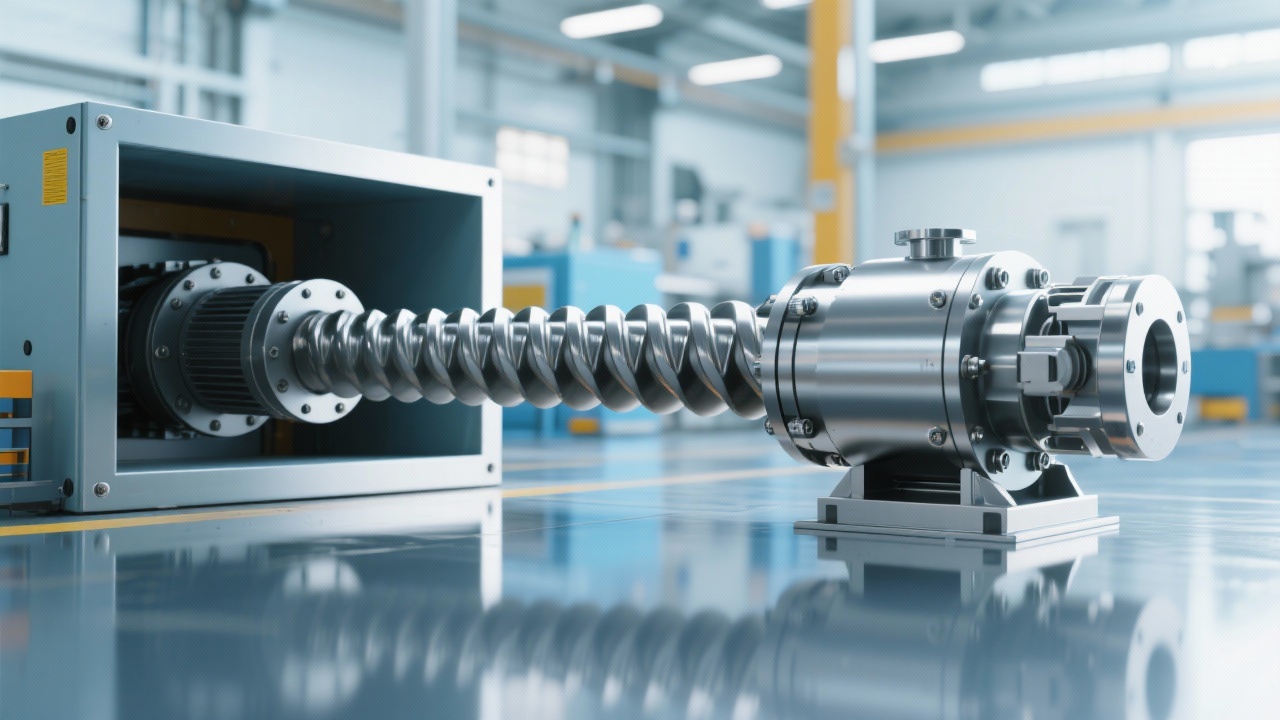

Heavy-duty screw conveyors are engineered to handle large volumes of bulk materials with robust construction to endure harsh industrial environments. The primary parameters influencing selection include:

- Conveying Distance: Typically ranges up to 30 meters for standard models, with custom designs extending beyond depending on power and shaft strength.

- Lifting Height: Common configurations support vertical lifts up to 6 meters, crucial for multi-floor facilities or complex production lines.

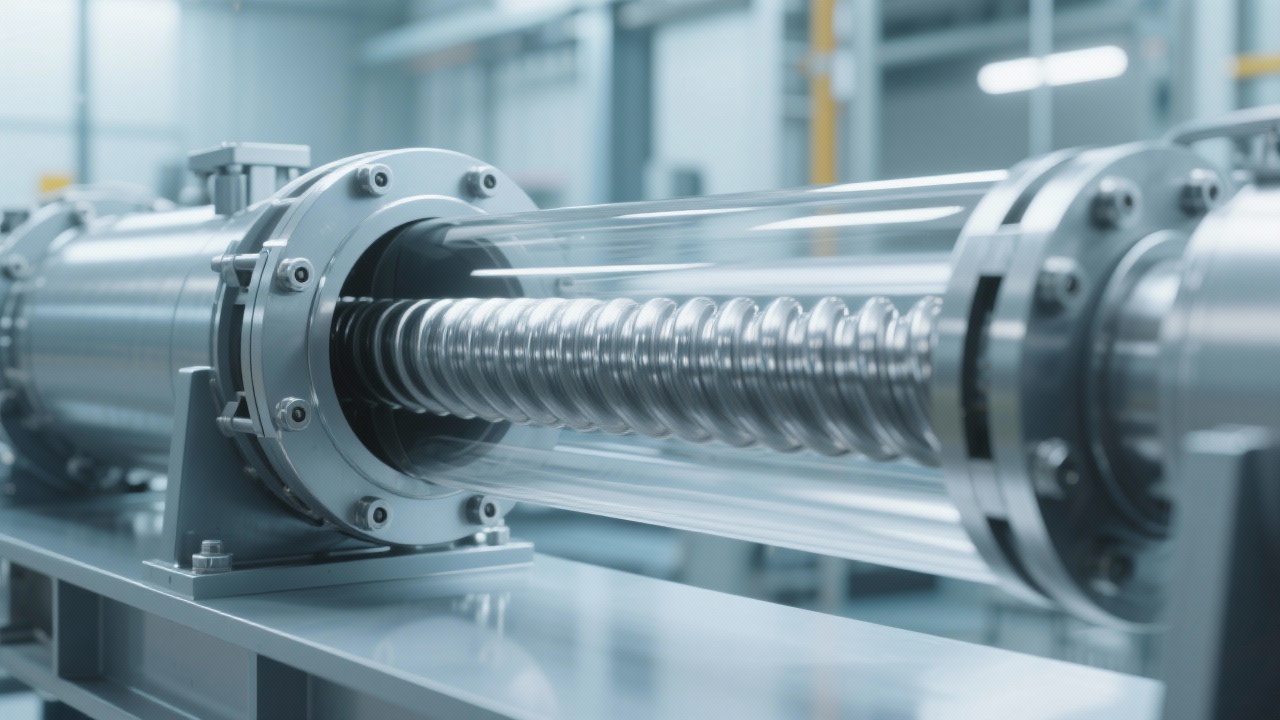

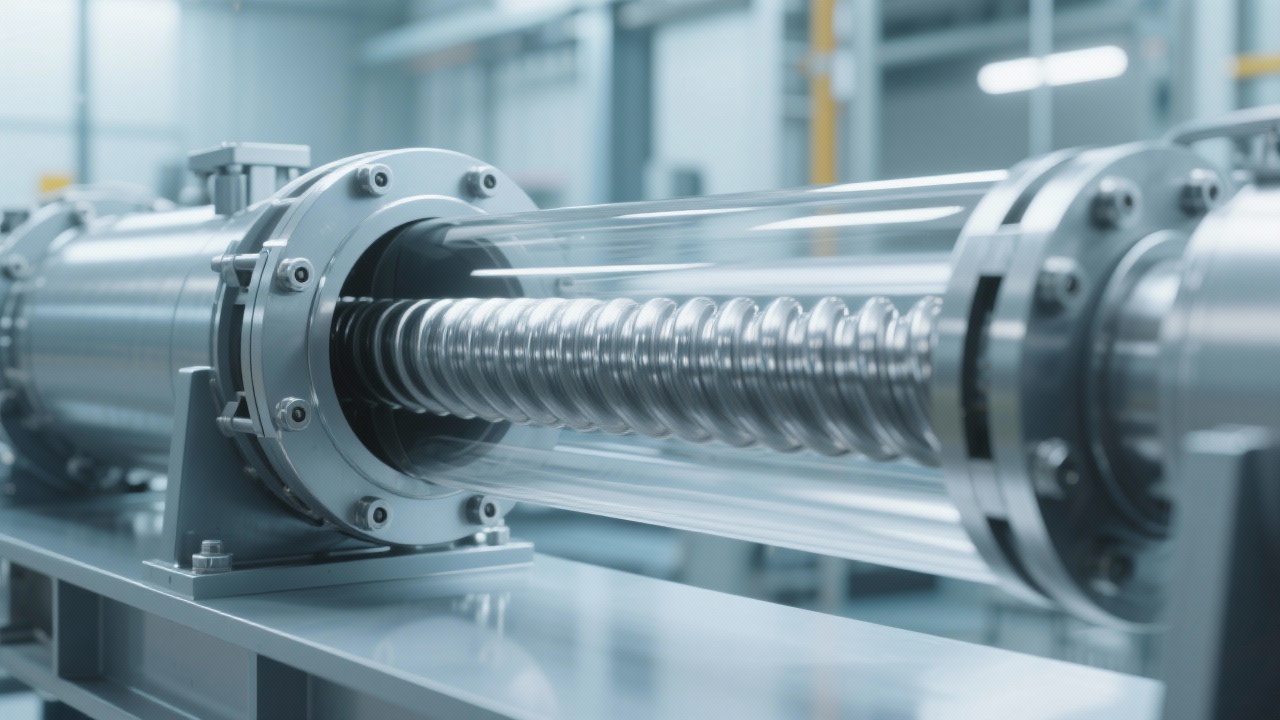

- Screw Rotor Design: Variable pitch and diameter rotors optimize material flow rate and reduce surge. Heavy-duty rotors withstand abrasive or dense materials, sustaining operational lifespan beyond 15,000 working hours.

Material-Specific Conveying Requirements

Different material states impose distinct demands on conveyor selection:

- Powdered Substances: Fine particulates require conveyors with airtight sealing to prevent dust emissions and contamination.

- Granular Materials: These demand moderate speed control to avoid segregation while ensuring steady throughput.

- Small Lumps: The screw pitch and trough clearance must accommodate irregular shapes without clogging or excessive wear.

Sealing Technology: Minimizing Dust Escape and Material Contamination

An integral feature of advanced heavy-duty screw conveyors is their sealed operation mechanism. The system incorporates labyrinth and mechanical seals at inlet and outlet points, coupled with pressurized air shields, effectively suppressing the escape of fine dust particles. This containment reduces environmental contamination, protects worker health, and ensures product purity. According to industry tests, sealing can cut particulate emissions by over 85% compared to traditional open models, supporting compliance with ISO 14644 environmental standards.

Multi-Point Feeding and Discharge: Enhancing Line Flexibility and Efficiency

Contemporary conveyors offer flexible configurations with multiple inlet and outlet points. This design supports various process stages simultaneously, enabling:

- Integration of diverse raw materials into a single transport line.

- Selective discharge reducing need for additional handling equipment.

- Optimized space usage within complex production layouts.

The resulting throughput gain can boost overall plant productivity by 15-25%, as validated in case studies with chemical manufacturing plants.

Industry Applications and Best Practices for Selection & Maintenance

Across mining, chemical, and construction sectors, these conveyors must conform to both operational and regulatory constraints. Selection should consider:

- Compliance: Materials and seals meeting ATEX and OSHA standards for hazardous dust environments.

- Maintenance: Easy access to seals and bearings for routine inspection to maintain >98% uptime.

- Customization: Ability to retrofit sensors monitoring load and dust levels ensures proactive operational management.

Implementing scheduled preventive maintenance significantly reduces unexpected downtimes by approximately 30%, optimizing total cost of ownership.