Industrial manufacturing continuously demands breakthroughs in material handling efficiency and environmental compliance. The challenge lies in selecting conveying equipment that balances high throughput, dust containment, and flexible integration within diverse production lines. Heavy-duty screw conveyors equipped with multi-point inlet and outlet configurations present a promising solution, particularly the TQ-SC series which excels in transporting powders, granules, and small lump materials under rigorous industrial conditions.

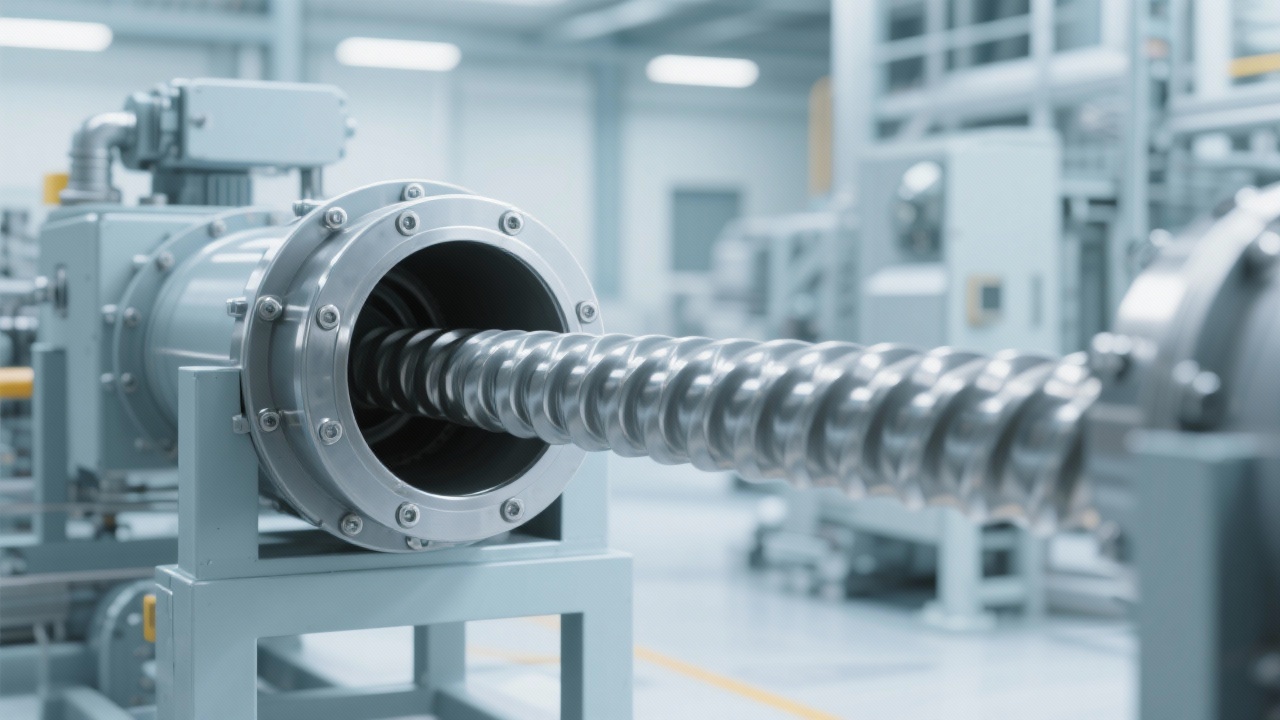

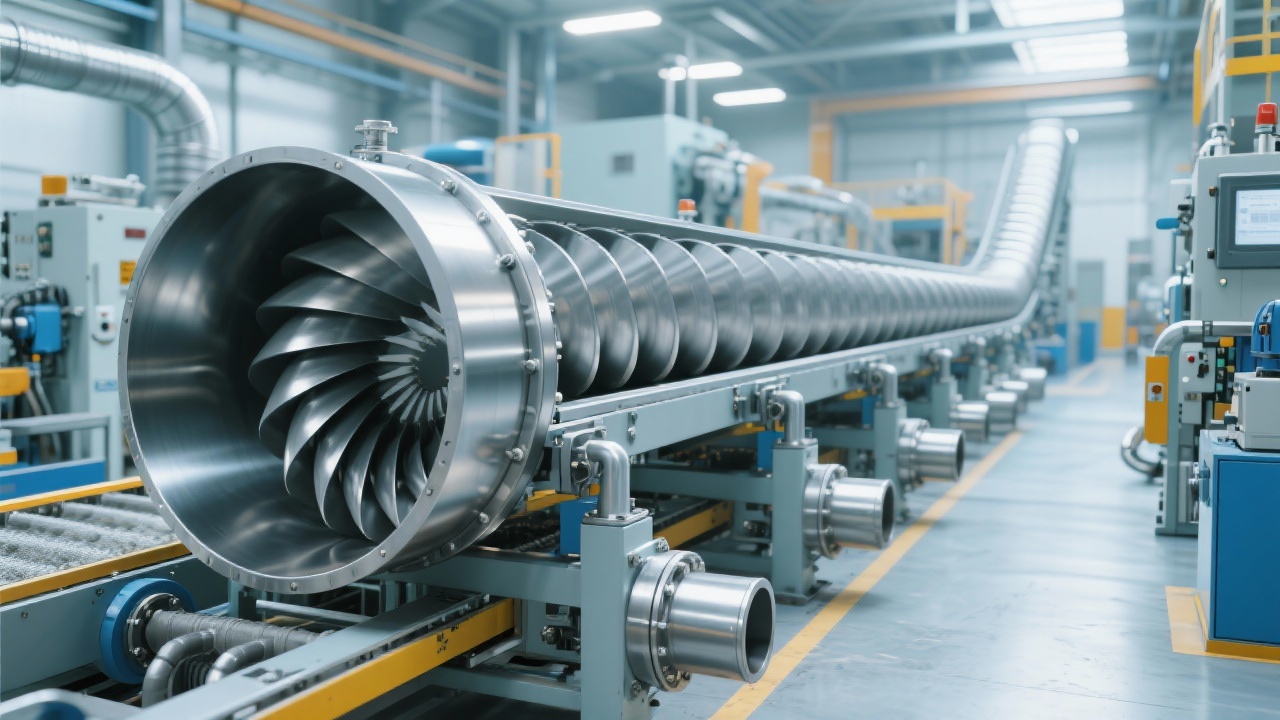

Screw conveyors operate on the principle of a rotating helical screw element within a trough to move bulk materials linearly. However, traditional single-point inlet or outlet designs often limit production line adaptability, complicate automation, and increase downtime. Additionally, industrial operators face issues such as material spillage, dust emissions impacting workplace health, and excessive maintenance costs linked to equipment wear under heavy loads.

The TQ-SC heavy-duty screw conveyor is engineered for vertical lifts up to 20 meters and horizontal transfers reaching 150 meters, accommodating diverse plant layouts. The screw rotor design optimizes pitch and diameter based on material granulometry: finer powders utilize tightly pitched screws for smooth flow, while coarser granules and small lumps require robust flights to prevent clogging.

This tailored approach not only maximizes throughput but also reduces energy consumption—a key sustainability metric for modern plants striving to reduce carbon footprints.

One of the primary environmental concerns with screw conveyors is fugitive dust emissions. The TQ-SC series incorporates advanced sealing technology featuring labyrinth seals and integrated dust extraction ports, which reduce particulate escape by over 85% compared to standard models. This results in compliance with stringent workplace safety standards and mitigates environmental liabilities.

The sealed design also prevents contamination risk when handling sensitive or hazardous materials, ensuring product integrity throughout the process.

Unlike single-point systems, multi-inlet and outlet screw conveyors enable simultaneous feeding and discharge at multiple locations, allowing:

This modular approach supports Industry 4.0 objectives by enhancing process agility and reducing manual intervention.

In one cement production facility, upgrading to multi-point TQ-SC conveyors eliminated process bottlenecks by allowing simultaneous powder and aggregate feeds, boosting throughput by approximately 15%. However, clients occasionally underestimate the impact of material abrasiveness on rotor wear. Selecting inappropriate screw materials and ignoring maintenance protocols leads to increased downtime and cost.

Understanding the relationship between material properties, conveyor load, and sealing integrity is essential for achieving reliable operations.

When selecting a heavy-duty screw conveyor, prioritize:

Adhering to these standards ensures maximum uptime and prolongs equipment lifespan.