In the industrial sector, the demand for efficient and dust - free material conveying solutions has been on the rise. Heavy - duty screw conveyors play a crucial role in meeting these requirements. This article will comprehensively introduce the TQ - SC heavy - duty screw conveyor launched by Zhengzhou Tianqi Machinery Co., Ltd., focusing on its product advantages and application scenarios.

The heavy - duty screw conveyor is widely used in various industries such as mining, food processing, and chemical engineering. In the past decade, the market demand for dust - free conveying equipment has increased by approximately 30% due to stricter environmental regulations and the need for higher production efficiency. The TQ - SC heavy - duty screw conveyor is designed to address these challenges.

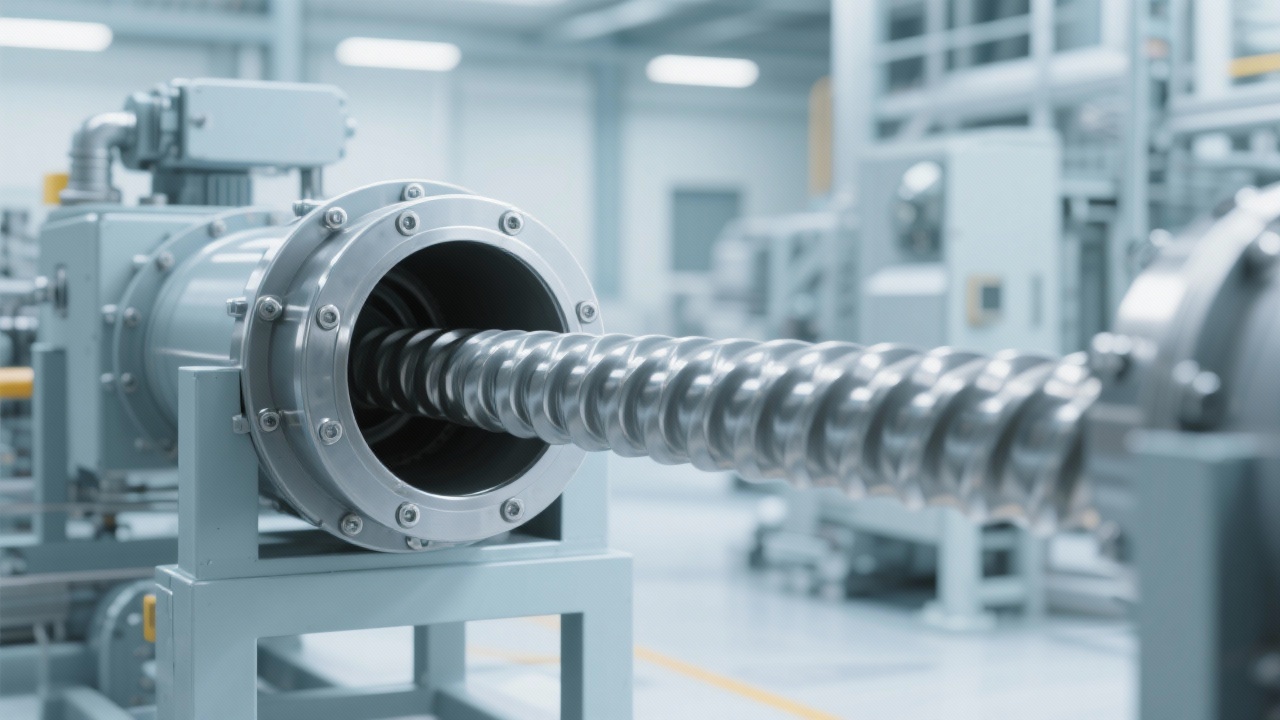

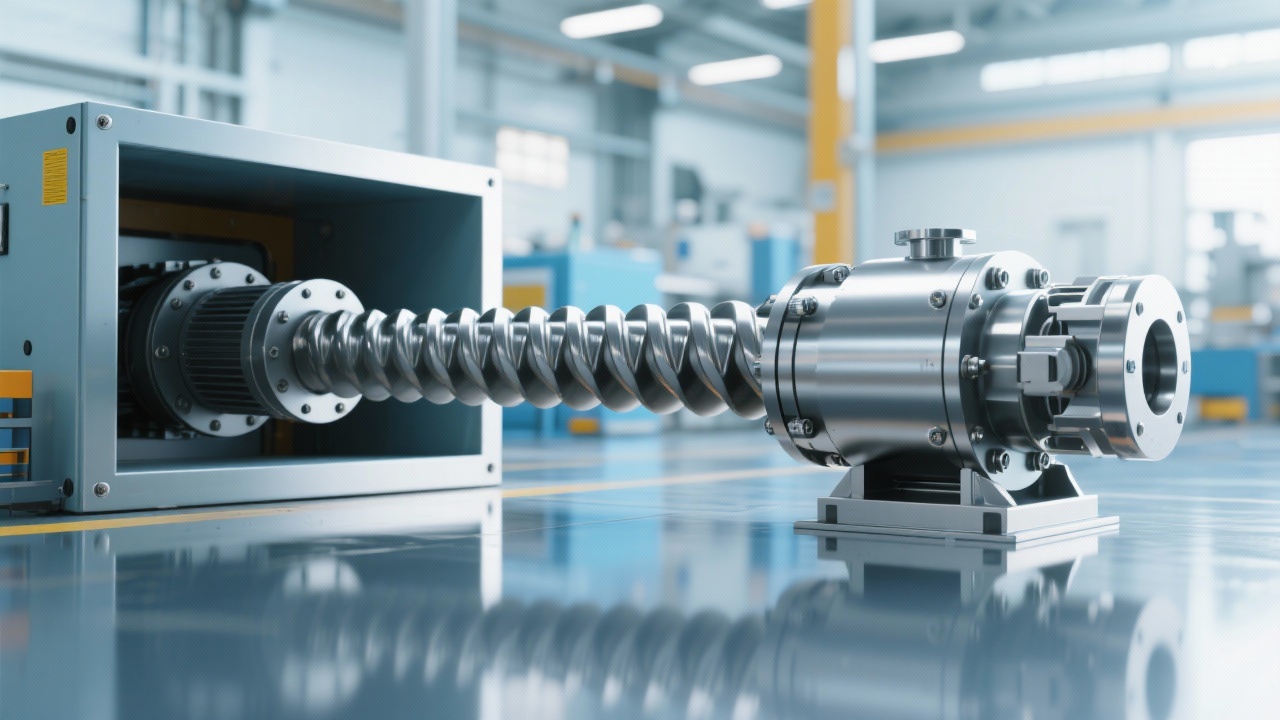

The performance of a screw conveyor is determined by several key parameters. The TQ - SC can achieve a maximum conveying distance of 50 meters and a lifting height of 15 meters. Its unique screw rotor design ensures a high - efficiency conveying capacity of up to 50 cubic meters per hour. These parameters are carefully calibrated to meet the diverse needs of different production lines.

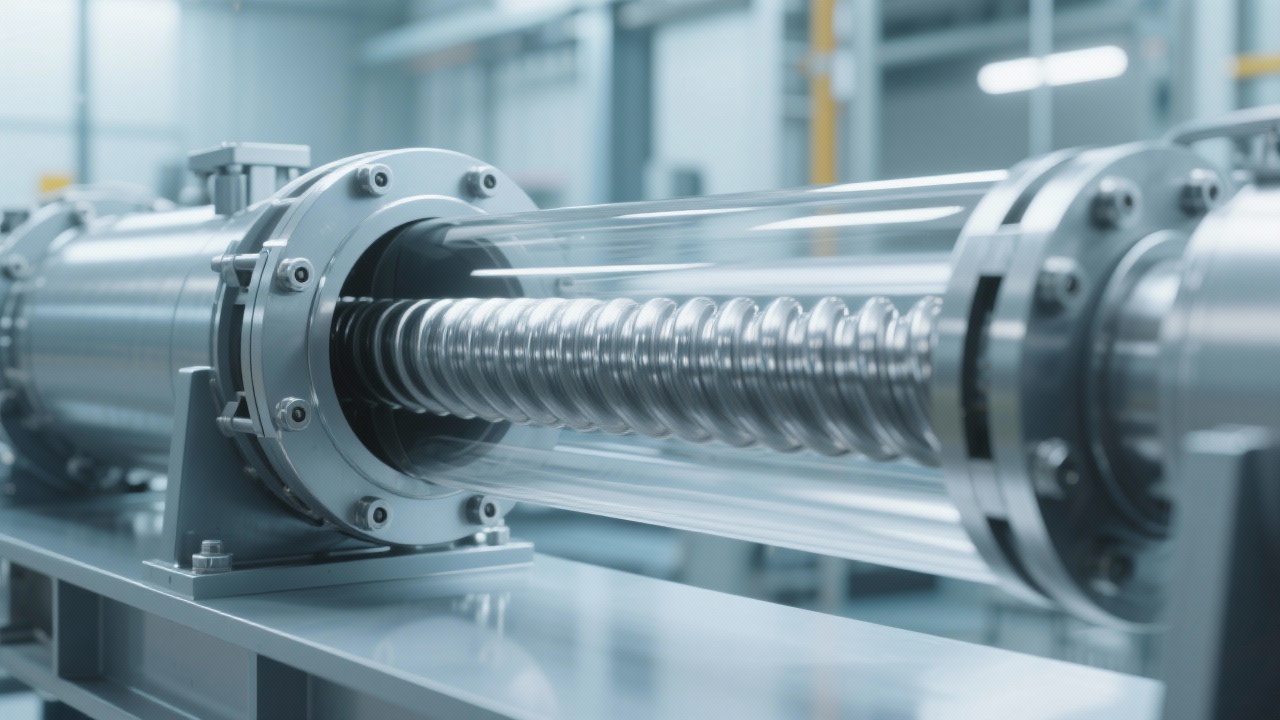

When it comes to conveying different materials such as powders, granules, and small chunks, the characteristics of the materials must be considered. Powders are more prone to dust generation, while granules and small chunks require a more robust conveying structure. The TQ - SC screw conveyor has been optimized to handle these materials effectively, reducing material loss and increasing conveying efficiency.

The sealing technology of the TQ - SC is one of its core advantages. By using advanced sealing materials and design, it can reduce dust dispersion by more than 90%. This not only improves the working environment but also reduces material waste. In a real - world case in a chemical plant, after installing the TQ - SC, the dust concentration in the workshop was reduced to within the national safety standard.

The TQ - SC features a robust structural design, which is made of high - quality steel. This ensures its long - term stable operation with a low maintenance cost. Compared with traditional screw conveyors, the maintenance cost of the TQ - SC can be reduced by up to 40%. This significant cost advantage makes it an attractive choice for many enterprises.

The multi - point feeding and discharging configuration of the TQ - SC allows it to adapt to complex production lines. It can be installed at multiple points along the production process, which can increase the production line efficiency by up to 25%. This flexibility makes it suitable for a wide range of industrial applications.

Based on real - world cases and technical data analysis, we provide a scientific selection guide for the TQ - SC heavy - duty screw conveyor. Enterprises can make more informed decisions by considering factors such as material characteristics, conveying distance, and production line requirements.

The TQ - SC heavy - duty screw conveyor from Zhengzhou Tianqi Machinery Co., Ltd. offers a comprehensive solution for dust - free and efficient material conveying. It combines advanced technology with practical applications, providing double guarantees for environmental safety and production efficiency. If you are interested in learning more about this high - quality product and how it can benefit your business, click here to contact us for free technical advice.