Selecting the right heavy-duty screw conveyor for efficient and dust-free material handling is crucial for businesses in industries such as mining, chemicals, and construction. This article aims to provide a comprehensive guide on how to choose the most suitable conveyor, covering three key dimensions: equipment performance parameters, material characteristics, and on-site environmental differences.

The performance parameters of a heavy-duty screw conveyor play a significant role in its ability to meet specific operational needs. Consider the following factors:

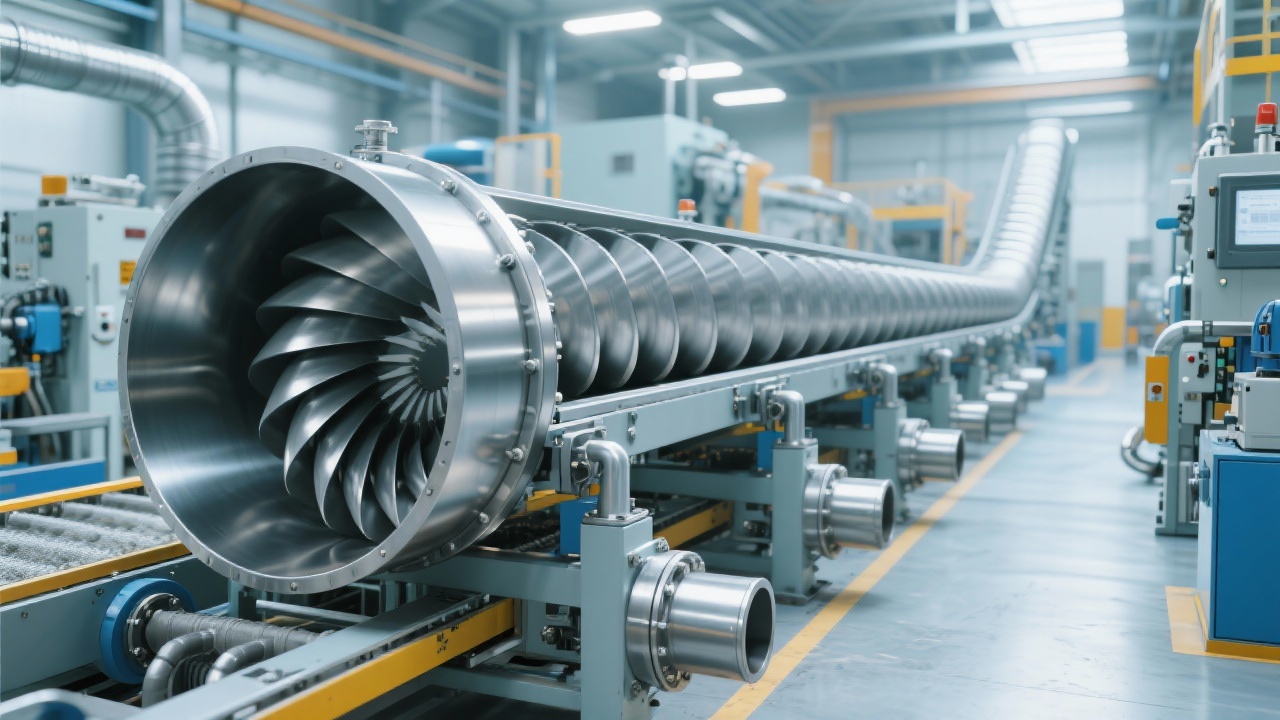

The conveying distance and lift height are directly related to the power and design of the conveyor. For instance, a longer conveying distance may require a larger diameter screw and a more powerful motor. Generally, for a conveying distance of up to 20 meters, a screw diameter of 200 - 300 mm is sufficient. However, for distances exceeding 20 meters, the screw diameter may need to be increased to 350 - 500 mm. Lift height also affects the design, as steeper inclines require more power to transport materials effectively.

The design of the screw rotor impacts the efficiency of material handling. A well-designed screw can ensure smooth and continuous flow of materials. For example, a variable pitch screw can increase the conveying speed and reduce the risk of material jams. Additionally, the screw's surface finish and material can affect wear resistance and cleaning ease.

The type of material being conveyed is a critical factor in conveyor selection. Heavy-duty screw conveyors are designed to handle various materials, including powders, granules, and small pieces.

Powdery materials, such as cement or flour, require a conveyor with excellent dust control capabilities. The sealing technology of the conveyor is crucial to prevent dust leakage and maintain a clean working environment. A conveyor with a high-quality sealing system can reduce dust emissions by up to 90%, ensuring compliance with environmental regulations.

Granular and small piece materials, like gravel or plastic pellets, need a conveyor with a robust structure to withstand the impact and abrasion. The screw design should be optimized to prevent material damage and ensure efficient conveying.

The on-site environment can significantly affect the performance and lifespan of a heavy-duty screw conveyor. Factors such as temperature, humidity, and the presence of corrosive substances need to be considered.

In high-temperature or high-humidity environments, the conveyor's materials and lubricants need to be selected carefully to prevent corrosion and mechanical failure. For example, in a hot and humid chemical plant, a conveyor with a corrosion-resistant coating and high-temperature lubricants is essential.

If the conveyed materials or the on-site environment contains corrosive substances, the conveyor's components, such as the screw and the housing, should be made of corrosion-resistant materials, such as stainless steel or special alloys.

Sealing technology is the key to dust control and ensuring the purity of materials. A well-sealed conveyor can prevent dust from escaping into the environment, protecting the health of workers and reducing the risk of product contamination. According to industry standards, a conveyor with a proper sealing system should have a dust leakage rate of less than 1%.

Zhengzhou Tianqi Machinery's TQ-SC heavy-duty screw conveyor uses advanced sealing technology to ensure efficient dust control and maintain the integrity of the conveyed materials.

The multi-point inlet/outlet configuration of a heavy-duty screw conveyor offers greater flexibility in production lines and better adaptation to automation. It allows materials to be fed and discharged at multiple locations, enabling more complex production processes. For example, in a large-scale mining operation, a conveyor with multi-point inlet/outlet can distribute materials to different processing areas efficiently.

Based on industry standards and real-world application scenarios, here are some practical suggestions for selecting a heavy-duty screw conveyor:

Selecting the right heavy-duty screw conveyor is essential for optimizing production line layout, improving operational efficiency, and ensuring environmental compliance. By considering the equipment performance parameters, material characteristics, and on-site environmental differences, you can make an informed decision. If you need further assistance or a customized solution, contact us today to get a free equipment matching recommendation.