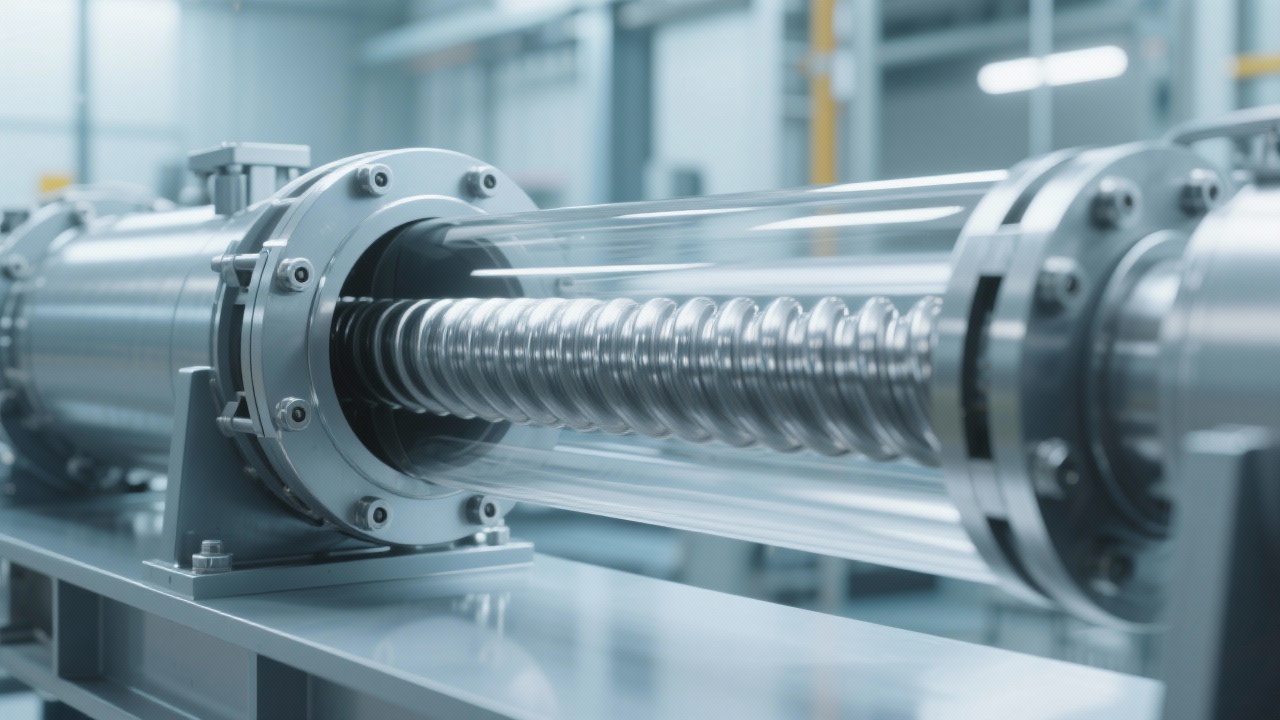

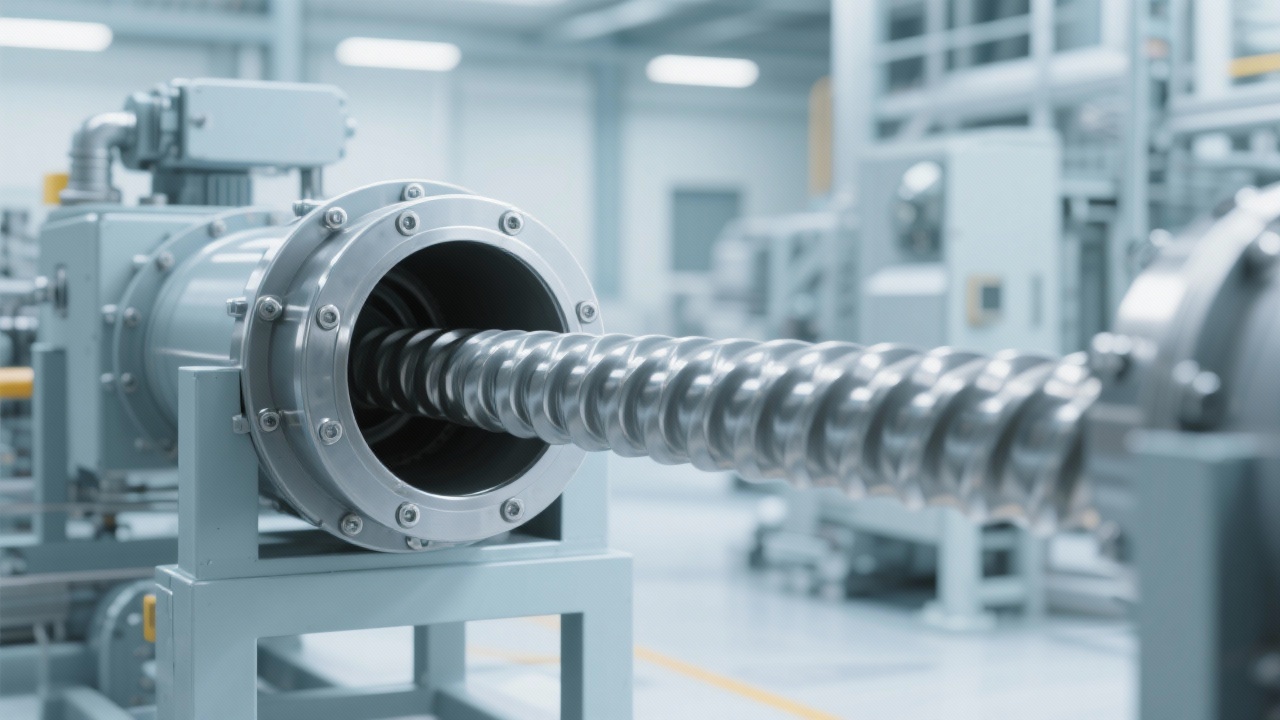

In the realm of industrial material handling, heavy-duty screw conveyors stand out as a reliable solution for efficient and dust-free material transportation. This article aims to provide a comprehensive guide on the selection and application of heavy-duty screw conveyors, focusing on their sealing operation technology and dust prevention advantages.

Before delving into the advanced features of heavy-duty screw conveyors, it's essential to understand the basic performance parameters. The type of material being conveyed can be classified into three main categories: powder, granular, and small块状. Different materials require different screw conveyor designs to ensure optimal performance. For example, powder materials are more likely to cause dust problems, so a well-sealed conveyor is crucial.

The conveying distance and lifting height are also critical factors. Generally, longer conveying distances and higher lifting heights require more powerful motors and sturdier conveyor structures. According to industry standards, for every 10 meters of conveying distance, the power requirement of the conveyor may increase by about 10 - 15%. This data provides a rough guideline for equipment selection.

Sealing operation technology is one of the core features of heavy-duty screw conveyors. It plays a vital role in dust prevention, reducing material loss, and avoiding environmental pollution. A well-sealed conveyor can effectively prevent dust from escaping into the air, which is not only beneficial for the health of workers but also meets the strict environmental requirements of industries such as mining, chemical, and construction.

Research shows that a conveyor with advanced sealing technology can reduce dust emissions by up to 90%. This significant reduction in dust not only improves the working environment but also reduces the risk of explosion in some industries where combustible dust is present. Moreover, it helps to minimize material loss, which can save costs for enterprises in the long run.

Multi-point feeding and discharging configuration is another key advantage of heavy-duty screw conveyors. This feature allows the conveyor to adapt to complex production environments and improve the flexibility of the production line. With multi-point feeding, different materials can be fed into the conveyor at different points, which is very useful in processes where materials need to be mixed or processed at different stages.

Similarly, multi-point discharging enables the conveyor to distribute materials to different locations, which is essential for large-scale production lines. For example, in a chemical plant, a conveyor with multi-point discharging can send different products to different storage areas or processing units, improving the overall efficiency of the production process.

Heavy-duty screw conveyors are known for their sturdy structure and low maintenance cost. The conveyor is usually made of high-quality steel, which can withstand heavy loads and harsh working conditions. This sturdiness ensures the long-term reliability of the equipment and reduces the frequency of breakdowns.

In terms of maintenance, compared with other types of conveyors, heavy-duty screw conveyors require less maintenance. According to industry statistics, the annual maintenance cost of a heavy-duty screw conveyor is about 20 - 30% lower than that of a belt conveyor of the same capacity. This low maintenance cost is a significant advantage for enterprises in the long - term operation.

To help procurement officers and technical decision - makers make more accurate purchasing decisions, it's useful to look at some real - world cases. In a mining company, after replacing the old conveyor with a heavy - duty screw conveyor with advanced sealing technology, the dust emission in the workshop was significantly reduced, and the production efficiency increased by about 20%. This case clearly demonstrates the benefits of using a high - quality heavy - duty screw conveyor.

When selecting a heavy - duty screw conveyor, it's important to consider all the factors mentioned above, including material characteristics, conveying distance, sealing technology, and feeding/discharging configuration. By making a comprehensive evaluation, enterprises can choose the most suitable conveyor to meet their production needs.

Heavy - duty screw conveyors offer a reliable and efficient solution for material transportation in various industries. By understanding their performance parameters, sealing technology, multi - point configuration, and other features, enterprises can make better purchasing decisions, improve production efficiency, and ensure environmental safety. If you are looking for a professional heavy - duty screw conveyor selection solution to enhance your material transportation efficiency, click here to learn more.